About Aerosols

Technically, an aerosol is a suspension of fine solid particles or liquid droplets in a gas. The word “aerosol” also refers to the dispenser or package used to change the ingredient inside the container into an aerosol.

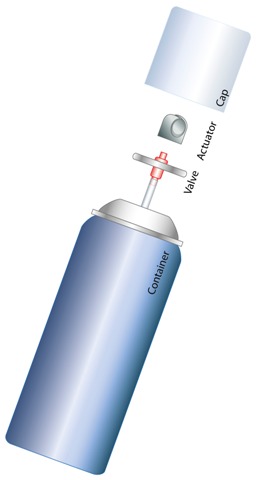

Although ‘aerosol’ refers to a finished product, it is made up of four components: the container, the valve, the actuator and the cap.The container can be made from different materials but is usually made of tinplated steel or aluminium. It provides optimal conditions to store the product to be sprayed.

Although ‘aerosol’ refers to a finished product, it is made up of four components: the container, the valve, the actuator and the cap.The container can be made from different materials but is usually made of tinplated steel or aluminium. It provides optimal conditions to store the product to be sprayed.

There is a wide range of container shapes and volumes available, depending on the final product characteristics and the gas used.

The valve operates as a non-visible component but its role is essential: it keeps the container airtight, clean and hygienic and regulates the flow of the product during use.

The actuator or button controls the angle, amount, shape and the fineness of the product spray. The type of content and the aerosol’s use are key factors in the selection of the actuator.

The cap functions as a seal and keeps the product contained until it is used. It also acts as a decorative component and harmonises the product’s appearance. Some caps act as an actuator for certain products.

The cap functions as a seal and keeps the product contained until it is used. It also acts as a decorative component and harmonises the product’s appearance. Some caps act as an actuator for certain products.

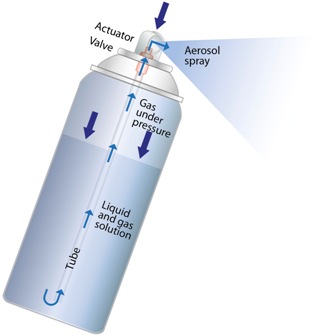

An aerosol container is a pressurised recipient containing:

- A propellant gas or a mixture of propellant gases which represents 5% to 90% of the product. These can be compressed gases or liquefied gases. Liquefied gases act as propellant gas and as co-solvent.

- One or more solvents

- Active ingredients dissolved or suspended in the liquid solvent concentrate

When you press the actuator or button, this activates the valve.

The propellant gas exerts pressure on the active product and solvent solution, forcing the liquid up through the dip tube and through the valve when opened, allowing the product to be expelled together with the propellant in the form of droplets, foam, paste or powder.